From towering billboards to eye-level street furniture, LED technology delivers unparalleled visual impact, captivating audiences with brilliant colors and crisp imagery. However, behind every stunning outdoor display lies a critical decision: the type of LED encapsulation. This choice, among DIP, SMD, and COB technologies, isn't just a technical specification; it directly impacts the screen's durability, brightness, viewing angle, and overall performance in the challenging outdoor environment.

Selecting the right LED encapsulation is paramount to ensuring your outdoor advertising investment shines brightly for years to come. In this aspect, what LED technology should I choose? This guide will give you some hints.

LED display screens utilize various encapsulation technologies to protect the LED chips and integrate them into modules. The primary technologies include DIP, SMD, and COB, each with distinct characteristics impacting performance, cost, and application.

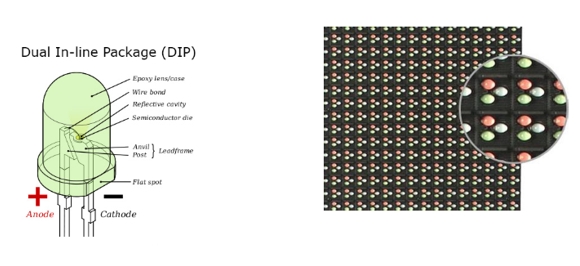

DIP, or Dual In-line Package, emerged in the late 1990s. This encapsulation technology involves directly inserting LED lamp beads into the PCB board and then soldering them to create display screen modules.

Initially, individual red, green, and blue (RGB) lamps were inserted into the PCB to form a pixel. Later, three RGB chips could be encapsulated within a single lamp bead, known as "three-in-one" outdoor displays, which improved production efficiency and reduced manufacturing costs.

SMD, or Surface Mounted Devices, is a surface-mount encapsulation technology that became prominent around 2002. It's one of the most common encapsulation methods on the market, suitable for pixel pitches ranging from P2 to P10.

In this process, LED chips are first encapsulated into individual lamp beads, which are then soldered onto the PCB board to create LED modules with different pixel pitches.

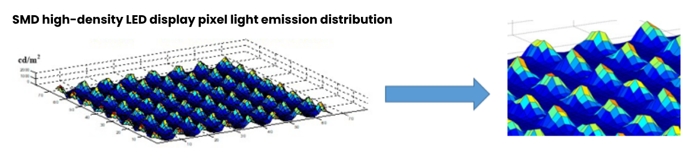

Each SMD LED lamp bead acts as an independent point light source. "Three-in-one" SMD technology, where RGB LED chips are encapsulated into a single SMT lamp bead, has become the standard for high-definition LED displays.

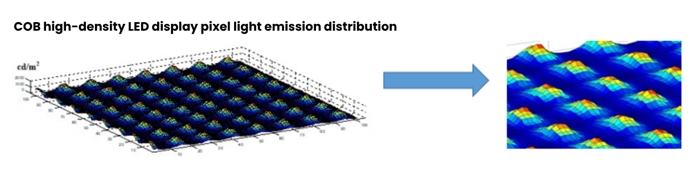

At its core, COB (Chip-on-Board) LED technology involves mounting multiple LED chips directly onto a substrate or Printed Circuit Board (PCB), forming a tightly integrated single module. Unlike SMD technology, where individual LED packages are soldered onto the PCB, COB directly integrates the chips onto the surface, almost as if they are "printed". This close arrangement of chips creates a highly uniform display surface.

This direct bonding method eliminates the need for individual LED packages and their associated copper bonding wires, a key differentiator from SMD technology. For instance, a 1080p SMD display might contain over 12 million copper bonding wires, which COB technology bypasses, contributing significantly to its unique performance characteristics.

Superior Visual Performance:

COB displays exhibit significant superiority in visual presentation. Their ability to package individual LED chips in extremely close proximity enables finer pixel pitches (e.g., less than P1.0) than SMD.

They also boast an impressive contrast ratio, often reaching up to 1,000,000:1 with superior color rendering capabilities. And more importantly, COB LEDs also produce a smoother, more uniform light distribution, effectively eliminating the "spotty" appearance, visible shadows, and hotspots sometimes seen with SMD displays.

Robustness and Durability

COB LEDs are renowned for their robust construction. The method of directly bonding LED chips to the substrate creates a sturdy and resilient connection.

Furthermore, COB often features resin encapsulation (similar to GOB – Glue-on-Board), which provides an extra layer of protection, effectively shielding the LED chips from environmental factors, moisture, and physical damage.

Energy Efficiency and Thermal Management

COB LEDs boast exceptional energy efficiency, offering up to 40% energy savings compared to traditional SMD displays of the same pixel pitch and size. This high efficiency stems from their direct mounting method and reduced resistance per pixel due to fewer components.

The reduction in componentry and the absence of copper bonding wires in COB displays significantly lower internal resistance, leading to improved thermal management.

Design Flexibility and Compactness

COB strip lights typically require no soldering and feature a more robust design, simplifying installation and reducing the need for protective end caps.

| Feature | DIP LED | SMD LED | COB LED |

|---|---|---|---|

| Brightness | Extremely High (up to 10,000 nits), suitable for direct sunlight | Moderate, balanced for indoor/outdoor, can have "spotlight" effect | Extremely High, superior uniformity, 40% more efficient than SMD |

| Resolution | Low, coarse display, large pixel pitch | High, finer pixel pitch than DIP, clear display | Extremely High, finest pixel pitch |

| Viewing Angle | Narrow effective angle, best viewed head-on | Wide (up to 160-180°), good for diverse audiences | Very Wide, uniform light distribution, excellent color consistency from angle |

| Durability | Excellent, robust construction, impact resistant | Good, but vulnerable at soldering joints, needs cooling | Superior, robust direct bonding, resin encapsulation, and better heat dissipation |

| Weather Resistance | Excellent, highly resistant to rain, dust, UV | Limited, weak resistance to environmental elements | Good, resin encapsulation for water/dust protection, emerging outdoor use |

| Cost | Lowest initial cost, cost-effective long-term | Moderate initial cost, higher than DIP | Highest initial cost, but cost-effective long-term due to efficiency/lifespan |

Then, if you are investing in outdoor advertising, which LED display screen should you choose? No worries, here is the pro advice:

Retop offers a range of LED display solutions specifically designed for outdoor advertising, emphasizing high performance, durability, and visual impact. Our main product categories include indoor and outdoor LED displays, LED modules, LED lighting, and sports stadium/arena displays.

For different requirements in outdoor advertising, we also provide multiple choices:

This series excels in 3D effects and high brightness, making it a top choice for impactful outdoor advertising. It features an ultra-light (9.6kg) and slim (80mm) design for easy transport and installation.

OPad supports flexible assembly for stunning 3D visuals and includes IP65 waterproofing, hidden cables, and efficient cooling for durability and a sleek aesthetic. It's ideal for portable LED walls and video panels.

Similar to the OPad, these series also stand out for their 3D effects and high brightness. The outdoor LED billboard offers flexible assembly options for captivating 3D displays and ensures vivid brilliance even in bright sunlight.

These displays are also IP65 waterproof, with hidden cables and efficient cooling systems, making them suitable for demanding outdoor environments and portable applications.

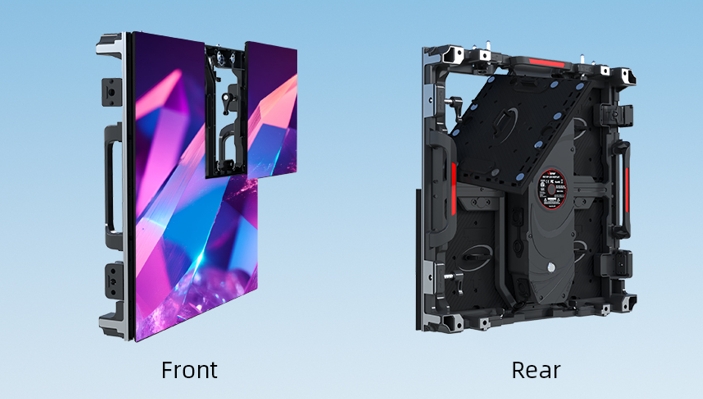

Designed for fixed outdoor installations, the OS series offers top-tier features for various applications, including digital billboards. These displays are ultra-light and slim for effortless transport and installation.

They feature an environmentally cooled design, high refresh rates (1920 ~ 3,840 Hz), and die-cast magnesium cabinets for enhanced durability and energy efficiency.

With an IP65 waterproof rating, they can withstand extreme weather conditions. The OS series also boasts quick installation features and stable aviation plug connections, ensuring reliable, high-quality performance for all outdoor advertising needs.

Pixel pitches for the OS series range from 2.5mm to 10mm, with brightness exceeding 5,000 cd/m².

Contact us for free consultation and more flexible outdoor ads display solutions.

I consent to receive emails about news, marketing&product updates from Retop in accordance with the Retop Privacy Policy